Der Weg zum fehlerfreien Lackierergebnis

Digitale Prozessoptimierungen für die Lack- und Farbenindustrie.Jeder, der Lacke oder Farben produziert oder mit ihnen arbeitet, weiß: schon kleinste Varianzen haben große Auswirkungen auf das Endergebnis. Fehler oder Unregelmäßigkeiten, die sich eingeschlichen haben, können den Produktionsprozess verzögern, Manpower binden, zu Lieferschwierigkeiten führen, Konfliktpotential mit Kunden bergen und den guten Ruf, den man sich in der Branche erworben hat, angreifen.

Damit es gar nicht erst soweit kommt, sollte man sich nicht auf die Fehlererkennung und -behebung verlassen, sondern eine Fehlervermeidung und Prozessoptimierung anstreben – Bereiche, in denen ORONTEC seit Jahren die Lack- und Farbenindustrie mit innovativen Lösungsvorschlägen unterstützt.

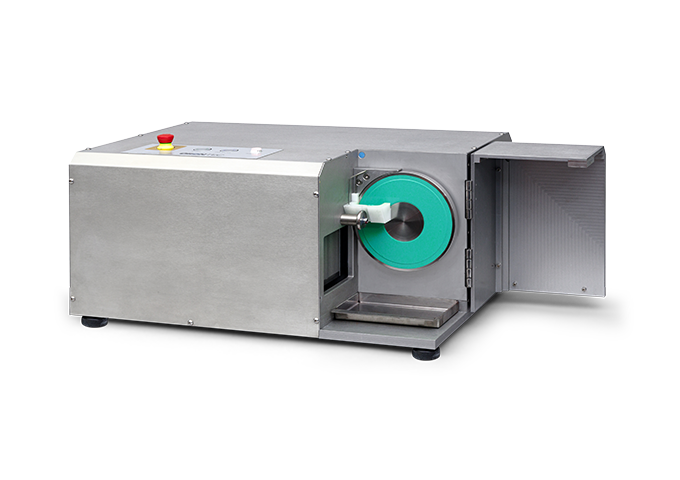

Die ORONTEC-Messautomaten

Für eine fehlerfreie Lack- und FarbenproduktionNachhaltige Vorteile durch intelligente Systeme.

Für einen reibungslosen Produktionsprozess:Die innovativen Lösungen und Systeme von ORONTEC verschaffen Produzenten der Lack- und Farbenindustrie nachhaltige Vorteile und unterstützen dabei Wettbewerbsfähigkeit zu sichern und Potenziale zu entwickeln. Die Automatisierung und Digitalisierung der Messprozesse:

- befreit den Prüfvorgang vom menschlichen Einfluss und eliminiert Fehlerquellen.

- verkürzt die Liefer- und Produktionszeiten.

- liefert verlässliche Ergebnisse an denen man sich auch in allen folgenden Produktionsprozessen orientieren kann.

- sorgt dafür, dass gut hochqualifizierte Mitarbeiter ihre Kapazitäten anderweitig einsetzen können.

- optimiert Produktionsprozesse unter ökonomischen und ökologischen Aspekten. Unter anderem kann eine Pigmentreduzierung und eine Einsparung bei den Kosten, bei Rohstoffen und Energie und beim Personaleinsatz erzielt werden.